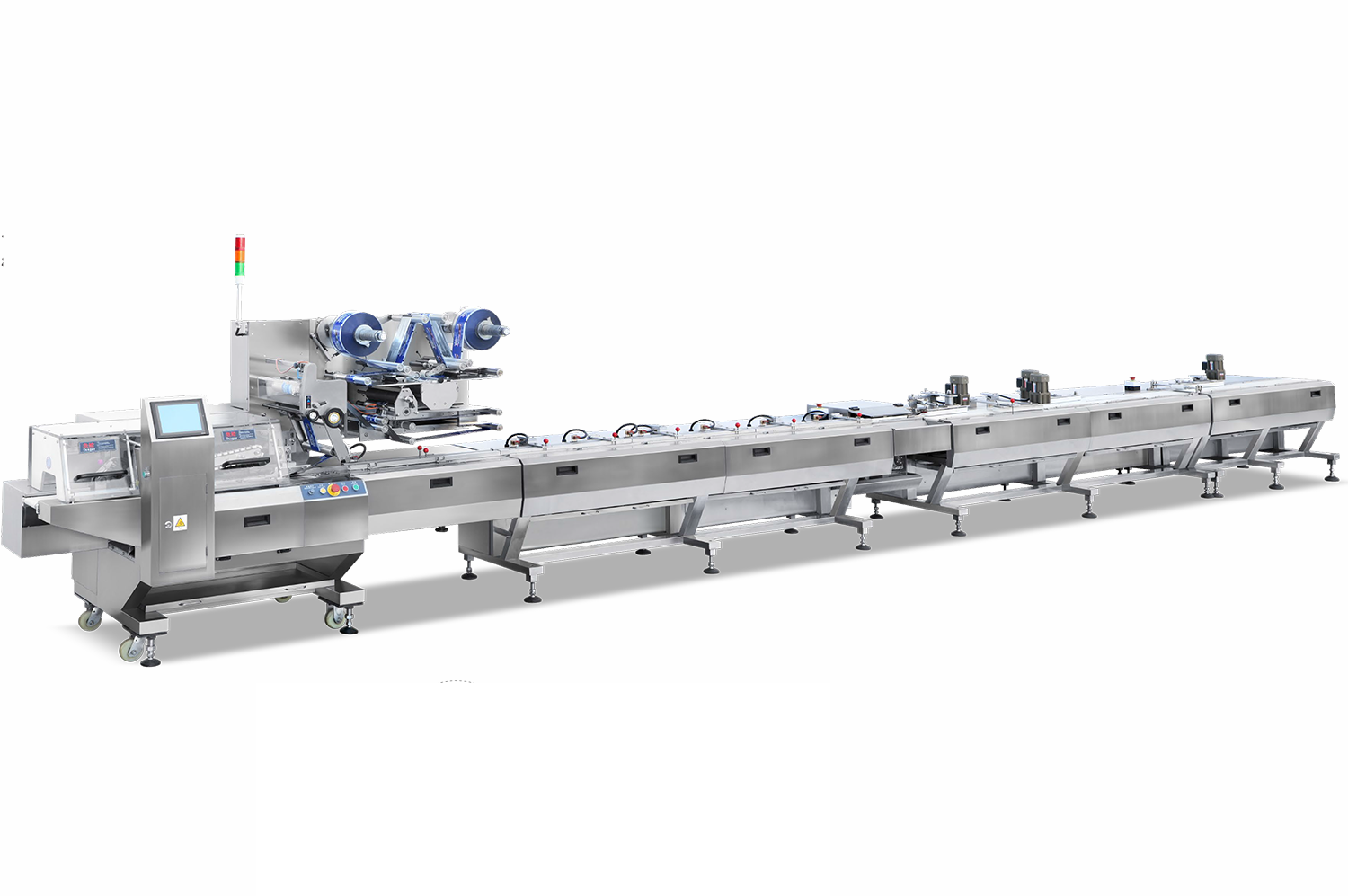

DXD-660高速自動理料枕式包裝線

USE用途

包裝機型號:DXD-660高速自動理料枕式包裝線

This machine is suitable for packing chocolate, wafer, confectionery,coated product and so on.

適用于巧克力,、威化,、膨化,、米果,、面包,、蛋糕,、瑞士卷,、糖果等及其涂層制品的包裝,。

自動理料枕式包裝線的主線物料分配系統(tǒng)采用中央集成控制系統(tǒng),,根據(jù)產(chǎn)品來料速度和數(shù)量自動調整分配,;理料單元通過伺服和PLC控制將產(chǎn)品有序,順暢,,無損傷的進入包裝系統(tǒng),,實現(xiàn)產(chǎn)品輸送,整理排隊,,供料自動化,,定位準確,無空包多包現(xiàn)象,;根據(jù)生產(chǎn)能力,,可選多級理料單元,包裝單元數(shù)量(包裝機可根據(jù)產(chǎn)品選配),。

The main line material distribution system of automatic material handling pillow type packaging line adopts central integrated control system, which can automatically adjust the distribution according to the product incoming speed and quantity; the material handling unit will enter the packaging system orderly, smoothly and undamaged through servo and PLC control, so as to realize the product transportation, sorting and queuing, automatic feeding, accurate positioning, and no empty and multi package phenomenon; according to the production capacity, the system has the advantages of easy operation, convenient operation and high quality , multi level material handling unit and number of packaging units (packaging machine can be selected according to the product).

MAIN TECHNICAL PARAMETERS包裝機的主要技術參數(shù)

DXD-660

Max.Production Capacity | z大生產(chǎn)能力 | 1200包/分(bags/min) | |||||||

Packing Range / Width Height | 包裝范圍(袋長由 切刀數(shù)決定)/ 袋長 寬度 高度 | 55-200mm 15-60mm 5-30mm | |||||||

Max.Dia.of Film | 包裝膜z大直徑 包裝膜z大寬度 | 390mm 300mm | |||||||

Gross Power Power Supply | 總功率 電源 | 9.6kw 380V 50Hz | |||||||

Gross Weight Overall Dimension | 總重量 包裝機外形尺寸 | 1600kg 9800×1000×1700mm | |||||||

Packing Material | 包裝材料 | OPP,、CPP、PET鍍鋁膜,、鋁塑膜,、紙塑,、紙膠等單層多層等可熱封材料 建議使用外層PET厚度0.013mm,內層CPP厚度0.023~0.027mm ,復合低溫膜 OPP、CPP,、PET Metallized film,,Al-plastic film,Paper-rubber complex Suggest to used wrapping film with material of PET13/CPP23-27 | |||||||

Note: We can design and manufacture according to customer's special needs. 注:用戶如有特殊規(guī)格,,本公司可另行設計制造.

Characteristics 包裝機特點

1 This machine is driven by servo motors, which helps achieve more

convenient operation and easier maintainance

2 This machine adopts wrapping film auto splice device, which helps

the machine achieves splicing of film without stopping machine

3 It adopts 304 stainless steel cover

4 Famous brand of control system, makes sure of stable working of

machine

5 Touch screen and plc help operating of machine more intuitive.

6 Adopts water chiller for chocolate products, to prevent chocolates

from being melt during packing.

7 To ensure fast packing speed, our machine uses 3sets of middle

seal wheels together with preheating.

8 The machine is equipped with remote control system, which makes

solving of program problems much easier.

1)伺服控制,,使得操作更加方便,維護更加簡單,;

2)自動接膜裝置,,實現(xiàn)了接膜不停機;

3)整機外殼采用304不銹鋼,;

4) 品牌的控制系統(tǒng),,保障了整機操作的穩(wěn)定性;

5)觸摸屏,,PLC使得操作更加直觀,;

6) 對于巧克力產(chǎn)品采用水冷結構,保護巧克力產(chǎn)品在包裝過程中

和設備的接觸面不易融化,;

7)三道縱封加預熱塊的設計,,保障了設備的高速運行;

8)包裝機配備遠程控制系統(tǒng),,能更加方便的解決軟件問題,。

理料線相關資訊

- 枕式包裝機的遠程監(jiān)控與數(shù)據(jù)采集:實現(xiàn)化管理

- 求精包裝機的客戶定制接口:輕松整合至現(xiàn)有生產(chǎn)線

- 理料線的未來趨勢:AI集成,,實現(xiàn)更別的自動化

- 枕式包裝機的創(chuàng)新包裝樣式:提升產(chǎn)品貨架吸引力

- 求精包裝機的創(chuàng)新設計理念:伴隨包裝行業(yè)新風尚

- 理料線的定制化服務:量身打造,滿足特定生產(chǎn)流程

- 枕式包裝機的兼容性材料廣泛:適應各種包裝膜材

- 求精包裝機的材料支持:推動可持續(xù)包裝解決方案

- 理料線的用戶友好的人機界面:簡單直觀,,操作便捷

- 枕式包裝機成為企業(yè)實現(xiàn)綠色板狀的理想選擇

- 求精包裝機的遠程監(jiān)控功能優(yōu)勢有哪些

- 理料線的故障自診斷系統(tǒng)介紹

- 枕式包裝機的節(jié)能降耗技術:綠色包裝,,先行

- 求精包裝機的遠程監(jiān)控功能:實時數(shù)據(jù)反饋,,管理無憂

- 理料線的故障自診斷系統(tǒng):快速定位問題,減少停機

- 深入了解理料線的工作原理與結構

- 求精包裝機:提升產(chǎn)品包裝品質的關鍵

- 理料線:自動化生產(chǎn)中的重要環(huán)節(jié)

- 枕式包裝機的節(jié)能降耗技術:綠色包裝,,先行

- 求精包裝機的遠程監(jiān)控功能:實時數(shù)據(jù)反饋,,管理無憂

- 理料線的故障自診斷系統(tǒng):快速定位問題,,減少停機

- 枕式包裝機的故障自診斷系統(tǒng)提升生產(chǎn)連續(xù)性

- 求精包裝機的包裝材料廣泛兼容:塑料,、紙張、薄膜等

- 理料線的數(shù)據(jù)追蹤功能